Transmission gear transmission

General variable speed gear called transmission gear. Transmission gear wear and tear of the reason is:

Transmission gear often at high speed, high load, speed and load under the condition of constant alternating work. Gear besides due to normal wear, also due to the lubricating oil quality, bad lubrication condition, improper operation and maintenance of driving gear assembly when inappropriate position of eating each other together, will impact gear, gear teeth chew well and started shaking, will accelerate the gear wear and damage. In addition, other parts of the gear or other wear parts (such as gear grooves in the hole, bearing wear, spline shaft, etc), deformation (such as the transmission housing and the bearing hole of the bearing wear or deformation, bending, etc.) of spline shaft, clutch or improper driving shaft assembly, to some defects in manufacturing, such as uneven carburized layer, gear warp, etc.), will also accelerate the wear of gear.

Structure size and material strength of the gear is rely on to withstand the load, which requires the material with high strength toughness and wear resistance; Due to the complexity of the gear shape, gear accuracy requirement is high, also requires a material good manufacturability.

Gears are commonly used material for forging steel

A, forged steel

According to the tooth surface hardness is divided into two broad categories

HB < 350, known as soft tooth surface

H8 > 350, called the hard tooth face

L. tooth surface hardness HB < 350

Process: forging blank to normalizing, rough turning, conditioning, and finishing

Commonly used materials; 45 #, 35 simn, 40 cr, 40 crni, 40 MNB

Features:

Has good comprehensive performance, tooth surface with high strength and hardness, tooth core has good toughness.

After heat treatment of gear cutting precision can reach 8.

Make simple, economic, high productivity, the accuracy is not high.

2. The tooth surface hardness HB > 350

When the medium carbon steel:

Process: forging blank - often turn to rough cutting to conditioning, fine cutting, high, medium frequency quenching and low temperature tempering to gear honing or abrasive running-in, edm running-in.

Commonly used materials: 45, 40 cr, 40 crni.

Features:

Tooth surface hardness HRC = 48-55, high contact strength, good abrasion resistance.

Tooth core keep after quenched and tempered toughness, good impact resistance ability, high bearing capacity.

Precision fell by half, the precision can be up to level 7.

Suitable for mass production, such as automobile, machine tools and so on medium speed of transmission gears.

Using low carbon steel:

Forging blank to often turn to roughing, conditioning, fine cut to carburizing and quenching and low temperature tempering, grinding. Level up to level 6, 7.

Commonly used materials; Cr, 20 crmnti, MNB 20, 20 crmnto.

Features: 'surface hardness, carrying capacity is strong.

Core good toughness and impact resistance, suitable for high speed and overloaded, overload transmission or requiring compact structure, locomotive main drive gear, aviation gear.

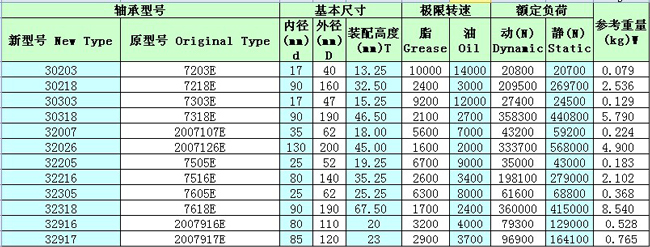

The transmission gears used bearing type

Second, the working conditions of the wheel is different, the destruction of the tooth form need not, is to determine the gear strength calculation according to the criteria and choice of materials and heat treatment.

1. For the impact load, the tooth is easy to break should choose good material toughness, can choose low carbon steel carburizing and quenching.

(2) for high speed closed transmission, tooth surface pitting, should choose tooth surface hardness, good material, can choose the medium carbon steel surface quenching.

3. Load in low speed, tooth broken, pitting corrosion, wear and tear can occur, should choose mechanical strength, good comprehensive mechanical properties such as tooth surface hardness material, can choose medium carbon steel quenched and tempered fine cut.

Related information

- Tapered Roller Bearings----Xingtai bearing give you best price

- The Great Wall lubricating oil testing services to provide clients with professional technology

- Shandong YunYu machinery group

- FOTON

- XingTai bearing congratulations on northwest bearing was awarded as "national intellectual property advantage enterprise"

- Qingdao reducer

Similar article ranking

Similar article ranking Latest information article

Latest information article